Baltimore’s port needed to be shut down, leaving thousands and thousands of tons of coal, tons of of automobiles, and deliveries of lumber and gypsum stranded.About 40 ships have been able to depart on Tuesday, and a giant variety of ships coming from the Atlantic can not dock “till additional discover,” because the port’s authorities stated.

Monetary markets reacted shortly to the bridge collapse, with shares of worldwide transport line Maersk plummeting 2.6% in Copenhagen on Wednesday.

However, an analyst from on-line dealer Nordnet informed the information company Reuters, in the long term, “this occasion will not be a serious catalyst for inventory costs, until one thing disagreeable comes up, like indications of gross negligence behind the accident.”

Gregory Daco, the chief economist at EY, additionally stays calm. “I believe the macroeconomic results will stay restricted,” he informed Bloomberg Information on Wednesday.

‘Path to normalcy’

US Transportation Secretary Pete Buttigieg warned of a “main and protracted influence to provide chains” following the closure of the Port of Baltimore. “It is too quickly to supply estimates on what it’s going to take to clear the channel and reopen the port,” he informed reporters throughout a briefing in Baltimore on Tuesday.

Buttigieg referred to the bridge as one of many “cathedrals of American infrastructure,” stressing that rebuilding it’s going to take time. “The trail to normalcy is not going to be straightforward,” he stated. “It is not going to be fast, it is not going to be cheap, however we’ll rebuild collectively.”

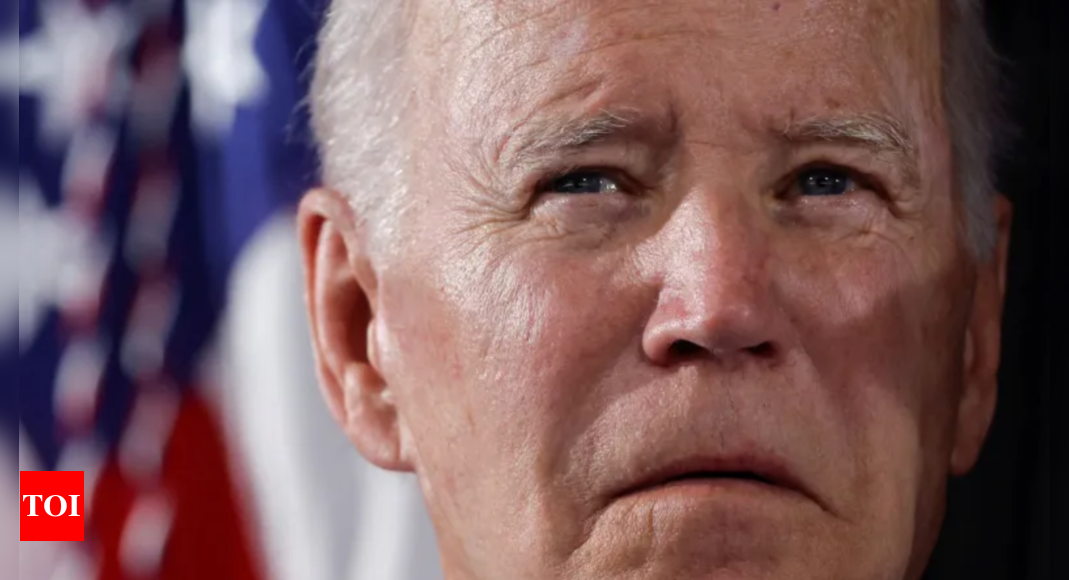

US President Joe Biden known as the collapse a “horrible accident,” and pledged to get the port reopened and the bridge rebuilt. “I intend for the federal authorities to cowl your entire value of rebuilding this bridge,” Biden stated in Washington.

Prices for rebuilding the bridge are estimated at $500 million to $1.2 billion (€462 million-€1.1 billion), with not less than two years of development time.

The Port of Baltimore is especially necessary for importing and exporting vehicles and lightweight vehicles. Roughly 850,000 autos are shipped there yearly, supporting round 15,000 jobs. Moreover, the Francis Scott Key Bridge is an important artery on the East Coast, with roughly 30,000 autos crossing the bridge each day.

Provide-chain worries reloaded?

European automakers, together with Mercedes, Volkswagen and BMW, preserve in depth infrastructure within the Baltimore area for automobile cargo.

A spokesperson for the German premium carmaker BMW stated in an e-mail to Reuters that the corporate doesn’t count on any rapid influence aside from short-term visitors delays. The corporate makes use of the Port of Baltimore to import autos, however the automotive terminal is situated on the harbor entrance, in entrance of the bridge, and may nonetheless be accessed, the spokesman added.

US automotive big Ford, nevertheless, must “divert elements to different ports,” which is able to influence its provide chain. Ford CFO John Lawler informed Reuters in a press release that “the place workarounds are crucial within the brief time period, our staff has already secured transport alternate options.”

Ryan Peterson, founder and CEO of logistics platform Flexport, stated that, with Baltimore dealing with just one.1 million containers in 2023, any influence on container charges and transport prices from the disruption could be far lower than will increase brought on by cargoes diverted on account of the assaults by the Houthi militant group within the Pink Sea.

“East Coast volumes are down and there’s the power for these ports to flex as much as deal with this,” he informed Bloomberg. He warned, nevertheless, of “visitors jams and delays” as a sudden improve in visitors at a port by 10% to twenty% could be sufficient to trigger all kinds of delays.

Ports in Germany

Ulf Kaspera, from the Federal Bureau of Maritime Casualty Investigation in Hamburg, sees no imminent hazard of an analogous accident taking place in Germany.

“The particular security measures to be taken rely upon the port operators,” he informed DW, noting that in Hamburg, for instance, it’s obligatory for big ships to be towed and maneuvered in extensive areas of the port. The usage of tugboats can “stop such accidents,” he stated.

Josef Hegger, from the Institute of Structural Concrete at RWTH Aachen College, stated the accident in Baltimore may have been prevented. The college lecturer is an knowledgeable in bridge development, and informed German information company dpa {that a} mixture of assorted structural measures can obtain the best stage of security.

“The pillar should have a sure resilience in order that it doesn’t collapse on the slightest influence,” he stated.

Germany’s Federal Waterways Engineering and Analysis Institute has established strict guidelines concerning the forces that bridge pillars should be capable of stand up to upon influence. As well as, so-called guardrails on bridges are supposed to stop collisions with the pillars.

“On the Rhine bridges, the big pillars and pylons are sometimes situated on the fringe of the river in order that the river opening is totally free,” Hegger stated. “If there’s a pillar within the center, it’s comparatively large and wedge-shaped and would deflect a ship that hits it.”

Hegger stated ships have been extra more likely to run aground there “earlier than hitting the pillar with full power.”